Home Electronics

Always by your side, with an advanced organizational strategy designed for flexibility, ensuring a fully personalized experience tailored to your needs.

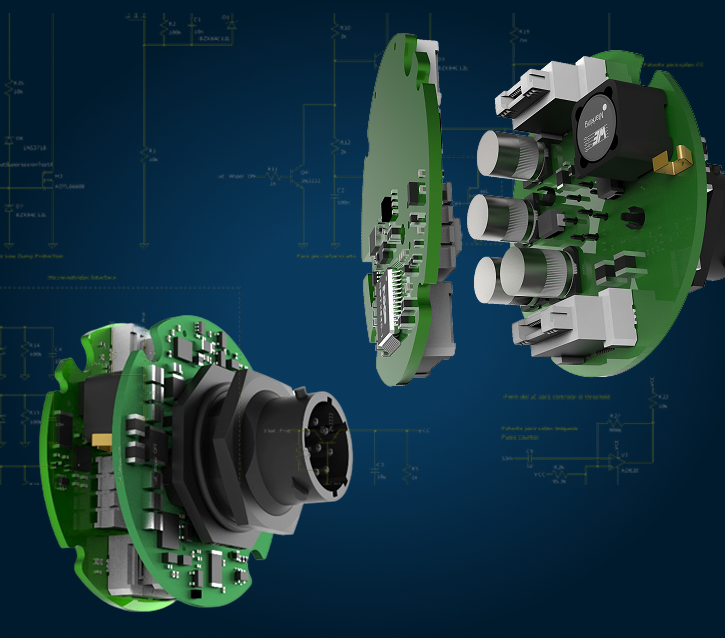

Wiper Systems, Drive Systems, and Tank Systems

Specialists In Wiper Systems, Drive Systems, Tank Systems And Other Systems Components.

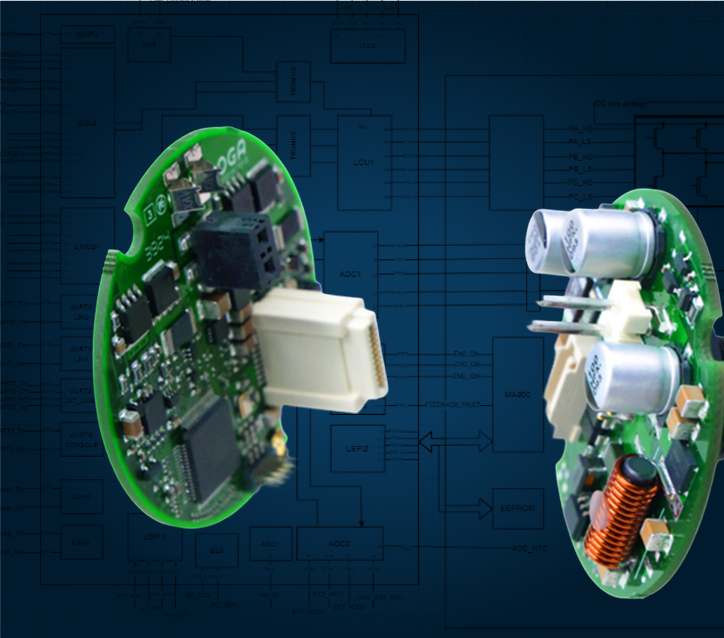

Integration with CANOpen, CAN J1939, and LIN

Wiper Systems, Drive Systems, and Tank Systems

Controllers for DC and BLDC motors

Compliance with ISO, UNE-EN, EMC, and mechanical testing

Integration with CANOpen, CAN J1939, and LIN

Controllers for DC and BLDC motors

Compliance with ISO, UNE-EN, EMC, and mechanical testing

The electronics development team is made up of highly qualified engineers from various specialties.

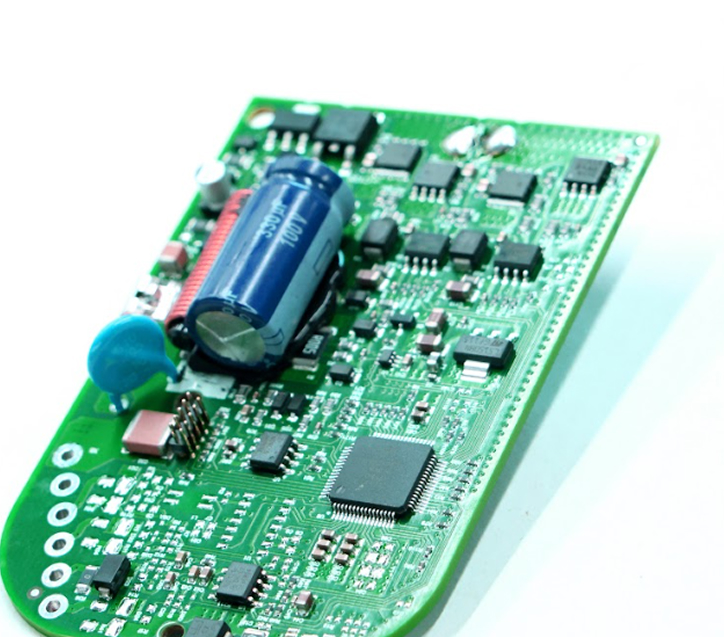

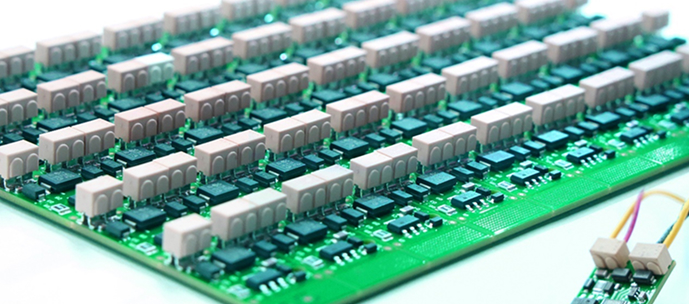

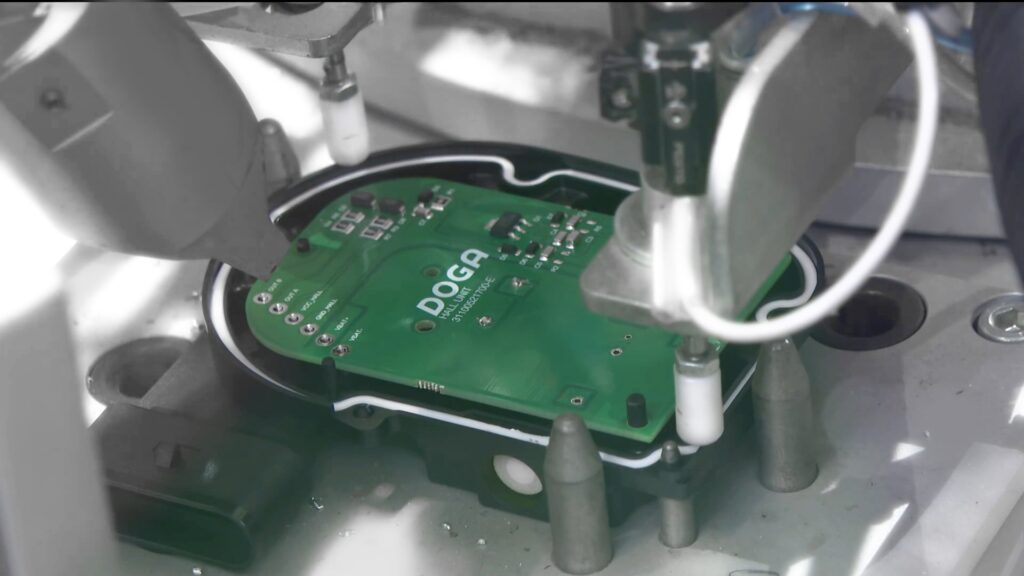

The hardware engineering team is responsible for designing controllers for DC and BLDC motors, complying with the strictest international standards and any specific customer requirements. They use Altium for hardware design and rely on P-Spice models for calculations and simulations.

The firmware engineering team implements algorithms for DC and BLDC motors using advanced control techniques such as PID and FOC. Firmware is developed in C and assembly language, with automated processes in place for static code analysis, unit testing, and integration testing to ensure high quality.

We provide tailored electronic solutions, ensuring seamless system integration and compliance with industry standards.

DOGA’s Laboratory is the department responsible for carrying out validation and research testing of our products, ensuring that each one meets the highest quality standards. We specialize in electric and electronic motors, control units, mechanical actuators, and wiper systems.

ISO

(Customer-specific standards, adapted to their particular needs.)

UNE-EN

(European Rules)

Customer-specific standards, tailored to their particular requirements.

We perform tests on the electromechanical properties of motors, ensuring their performance complies with international standards.

We carry out thorough testing to verify the electrical characteristics of products, ensuring safe and efficient operation under various working conditions.

We evaluate the reliability and safety of the software in our control units and other electronic products, ensuring their integrity and long-term performance.

We conduct tests to ensure our products do not generate electromagnetic interference and are resistant to external disturbances.

We simulate extreme conditions of temperature, humidity, and other environmental factors to assess our products’ resistance to corrosion and wear.

We perform tests that simulate real-use conditions to verify the products’ resistance to mechanical stress and vibrations.

Medimos los niveles de ruido de nuestros productos para cumplir con los requisitos acústicos y ofrecer productos que garanticen un rendimiento silencioso y cómodo.

We carry out tests in accordance with international standards, such as those established by the Society of Automotive Engineers (SAE), to evaluate product durability throughout its lifecycle.

We tailor our tests to each customer’s specific requirements, providing customized solutions that comply with their regulations and specifications.

We have advanced equipment and state-of-the-art technology to carry out a wide range of tests covering different areas of product development and manufacturing.

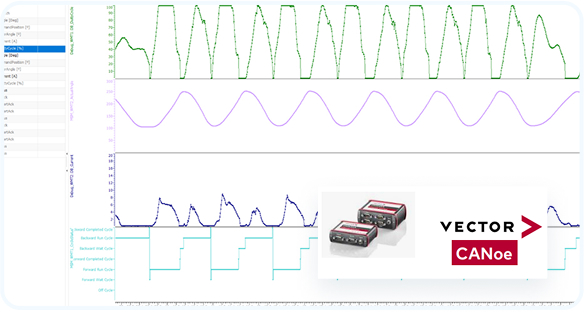

In the validation and testing area for electronic products, we apply advanced testing methodologies tailored to the most demanding communication and functional standards. We develop custom test environments based on the specific requirements of our products and our customers. This allows us to ensure that each device undergoes detailed and effective testing under controlled conditions.

To achieve this, we use state-of-the-art tools and software platforms that enable complex and precise testing. Our working methodology not only guarantees product reliability but also promotes continuous improvement and adds value to both DOGA and our customers.

At DOGA, we are committed to delivering products of the highest quality, using cutting-edge technology and advanced validation and testing methodologies. Thanks to our infrastructure, expertise, and collaboration with external laboratories, we ensure that every product meets the most stringent international standards, providing innovative technological solutions that benefit both our company and our customers.

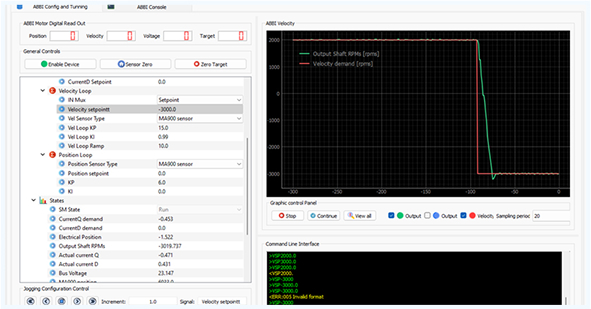

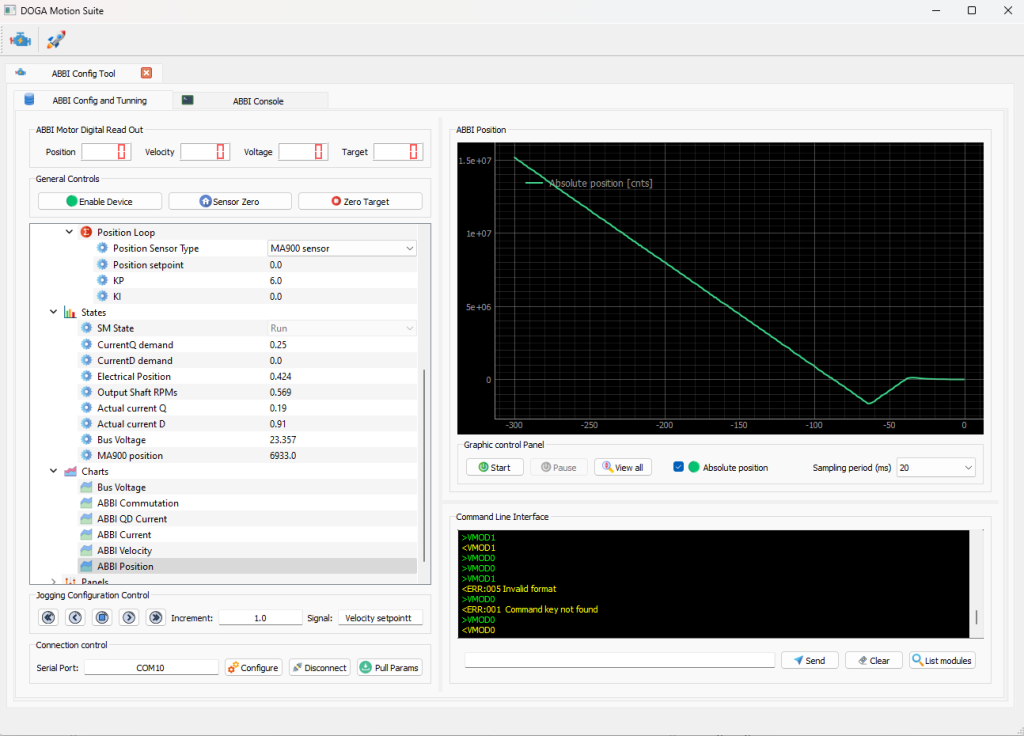

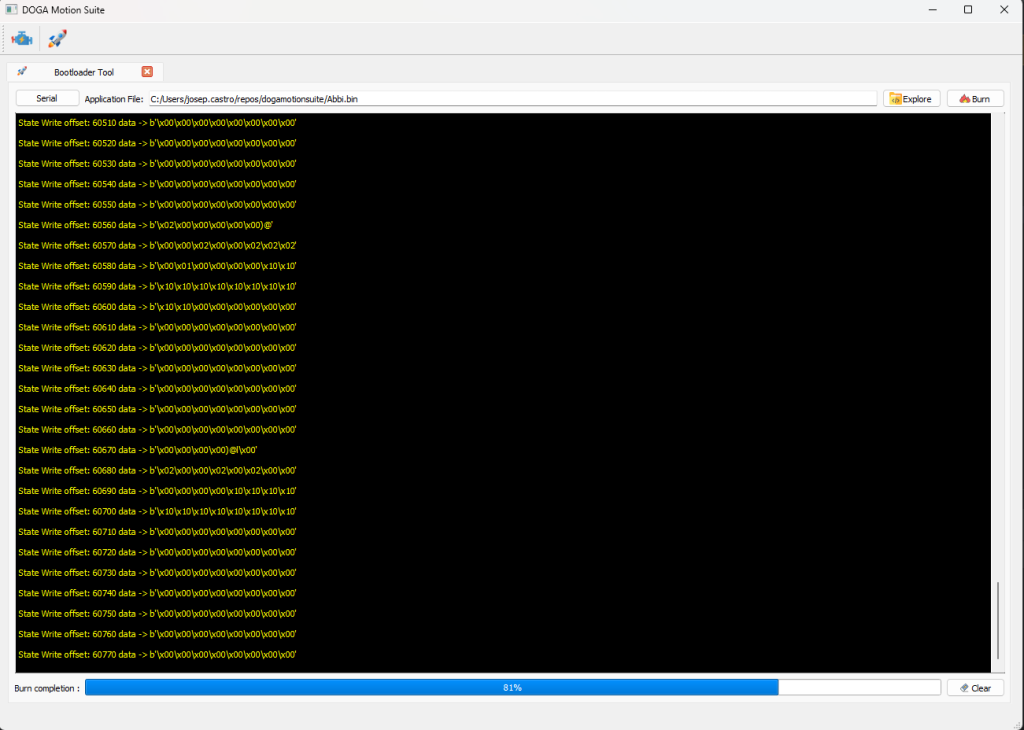

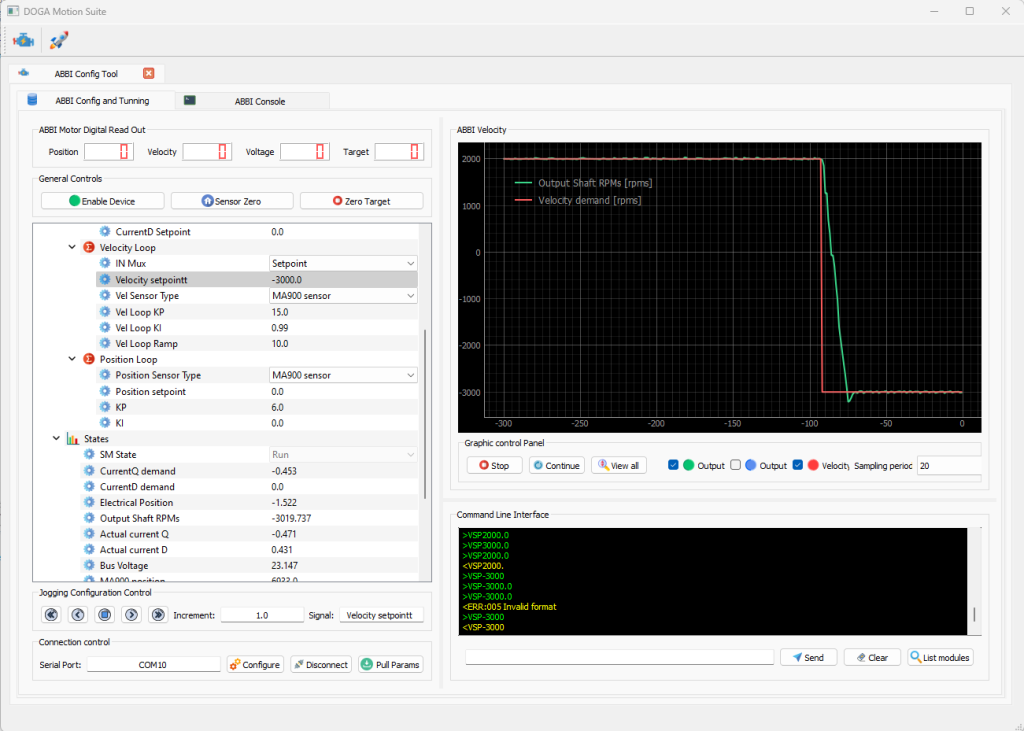

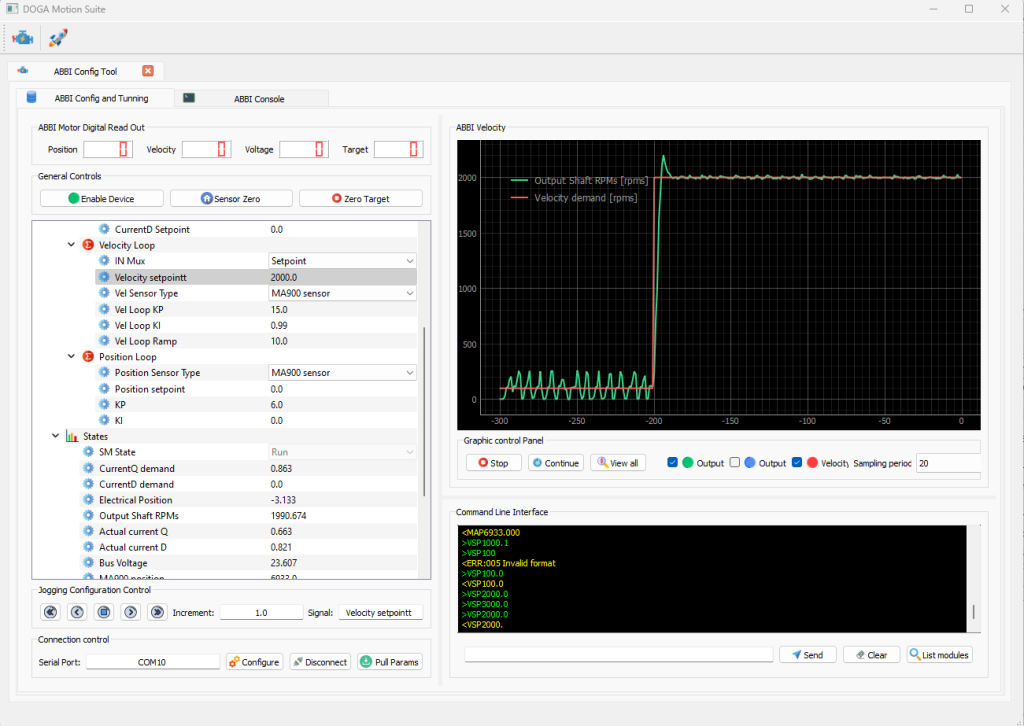

We also offer the possibility of developing custom desktop software for integrating the electronic motor into the client’s application. This enables motor parameter configuration, access to diagnostics, and direct motor control.

An example of this is our ECTIS application, which allows advanced configuration, monitoring, and control of DC and BLDC motors. It uses artificial intelligence to automatically optimize motor parameters based on performance and operating conditions, enabling faster and more precise adjustments.

This tool enables rapid system commissioning and offers remote support when needed.

Data controller: DOGA, S.A. Purpose of the data: web contact via form. Legal basis: your consent. Data storage: database hosted by OKITUP, S.L. Rights: You can limit, retrieve, and delete your information at any time.